Upgrading pre and post-labelling product handling is often seen as a cost. But for many manufacturers, it’s one of the fastest-returning investments they can make.

By automating product spacing, orientation, inspection, and rejection, food, beverage, and pharmaceutical production managers can unlock measurable gains in speed, quality, and labour efficiency, often seeing payback in months, not years.

At ALS Identify, we design and build solutions that deliver long-term value while solving today’s bottlenecks. Here’s how to assess the real ROI of automated product handling.

Direct Labour Savings

Manual tasks like product orientation, spacing, and reject removal require constant operator attention. Automating these steps allows you to:

- Reduce the number of operators required per line

- Reassign operators to higher-value activities such as changeover management or quality analysis

- Minimise overtime costs caused by slow or unpredictable runs

Example: One ALS Identify customer reduced operator involvement by 2 hours per shift, saving the equivalent of €35,000 per year in labour costs.

Reduced Waste and Rework

Every incorrectly labelled product represents wasted packaging, product, and labour. Vision inspection systems identify issues instantly, allowing non-compliant products to be removed before more resources are invested.

- Less scrap

- Fewer rework runs

- Lower disposal costs

Example: A beverage manufacturer reduced labelling errors by 60% in the first three months after installation.

Higher Throughput

Bottlenecks in spacing, orientation, or rejection processes slow the whole line. Automated product handling systems keep the labeller running at its rated speed without unplanned stops.

- More units per shift

- Faster changeovers

- Increased capacity for seasonal or promotional runs

Example: A pharma producer increased line output by 18% without adding shifts, simply by installing automated spacing and rejection systems.

Compliance and Brand Protection

In regulated industries, a single mislabelled product can trigger recalls, fines, or reputational damage. Inline vision inspection ensures every label is:

- Correctly applied

- Clearly printed

- Fully compliant with barcode readability requirements

Example: One ALS Identify project prevented a potential recall by detecting a batch-wide print quality issue before shipment.

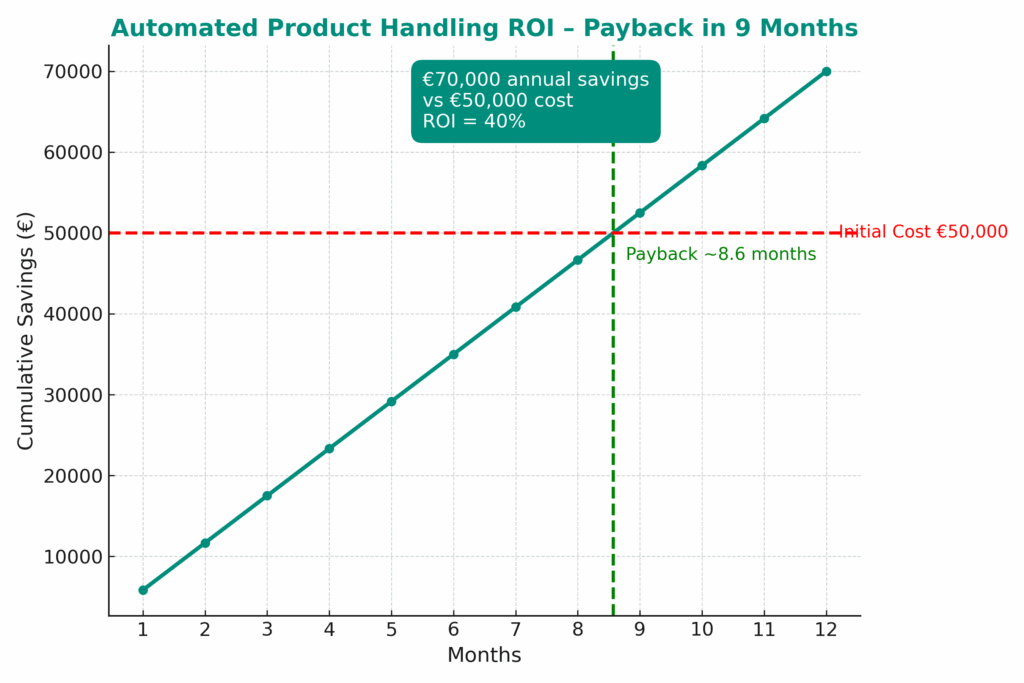

Faster Payback Than You Think

Here’s a simplified ROI calculation you can adapt to your own facility:

Annual savings from automation:

- Labour reduction: €35,000

- Waste reduction: €15,000

- Downtime reduction: €20,000

Total savings per year: €70,000

If your automated product handling upgrade costs €50,000, that’s a payback period of just 9 months, with continued savings every year after.

Why Work With ALS Identify?

- Guaranteed Irish – Local design, build, and service support for faster turnaround and minimal downtime.

- Custom-built – Every system is engineered for your product range, speed targets, and factory layout.

- Integration expertise – We ensure seamless compatibility with your existing labellers, conveyors, and controls.

The ROI of automated product handling isn’t just in speed, it’s in labour savings, waste reduction, compliance protection, and increased capacity. For many manufacturers, the numbers add up to a faster, more profitable operation.

Want to calculate your own ROI?

Download our free Buyer’s Checklist and discover exactly what to consider when planning your next automation upgrade.